RECO Mini CNC Turning center

RECO Mini CNC Turning center(GANG TYPE)

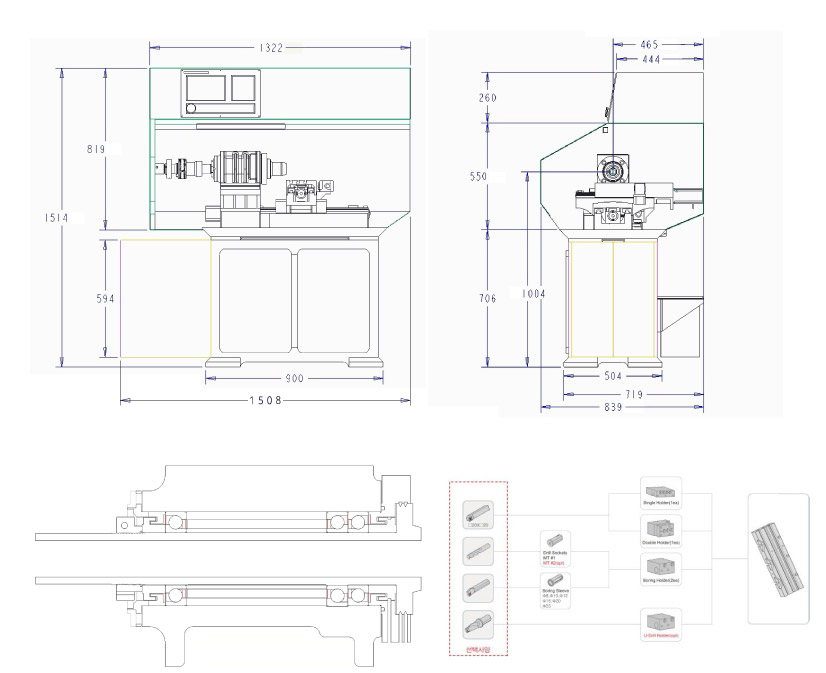

BED CONSTRUCTION

RIGID & HIGH ACCURACY ONE-PIECE CASTING BED Bed Design provides strong rigidity and minimizes vibration for the heavy duty cutting and high accuracy of precision machining.

ZERO-BACKLASH & ZERO-VIBRATION MECHANISM Each axis(X/Z) AC Servo motors are directly connected to ballscrews to provide “ZERO” Backlash and “ZERO” vibration.

COLLET CHUCK

Standard collet chuck minimizes chucking time over 30% in a high speed. accuracy, reduces spindle up and down time.

AUTOMATIC LUBRICATION

Adopted Auto Lubrication unit to properly supply oil to guideways, ballscrews and all necessary parts during the machine running.

SYMMETRICALLY HEAT BALANCED HEADSTOCK

Adopted angular contact ball bearing high precision headstock with minor temperature changes, it will minimizes thermal deformationin at all different RPM speed and produce superior surface finishes and roundness.

HYDRAULIC CHUCK

Adopted Hydraulic Chuck (3 Jaw Chuck / Collet Chuck) with rotary hydraulic hollow cylinder to assure the rigidity and for stability of high accuracy and precise machining.

- Bed Design provides strong rigidity and minimizes vibration for the heavy duty cutting and high accuracy of precision machining.

- Each axis(X/Z) AC Servo motors are directly connected to ballscrews to provide “ZERO” Backlash and “ZERO” vibration.

- Standard collet chuck minimizes chucking time over 30% in a high speed. accuracy, reduces spindle up and down time.

- Adopted Auto Lubrication unit to properly supply oil to guideways, ballscrews and all necessary parts during the machine running.

- Adopted angular contact ball bearing high precision headstock with minor temperature changes, it will minimizes thermal deformationin at all different RPM speed and produce superior surface finishes and roundness.

- Adopted Hydraulic Chuck (3 Jaw Chuck / Collet Chuck) with rotary hydraulic hollow cylinder to assure the rigidity and for stability of high accuracy and precise machining.

[contact-form-7 id="2345" title="product inquire"]